A NEW report setting out how Stanlow's first hydrogen production plant will benefit tens of thousands of energy consumers and businesses has been published.

Vertex Hydrogen, the joint venture between Essar Oil UK and Progressive Energy, has unveiled the report, detailing the development of the UK’s first ever large-scale low carbon hydrogen production plant.

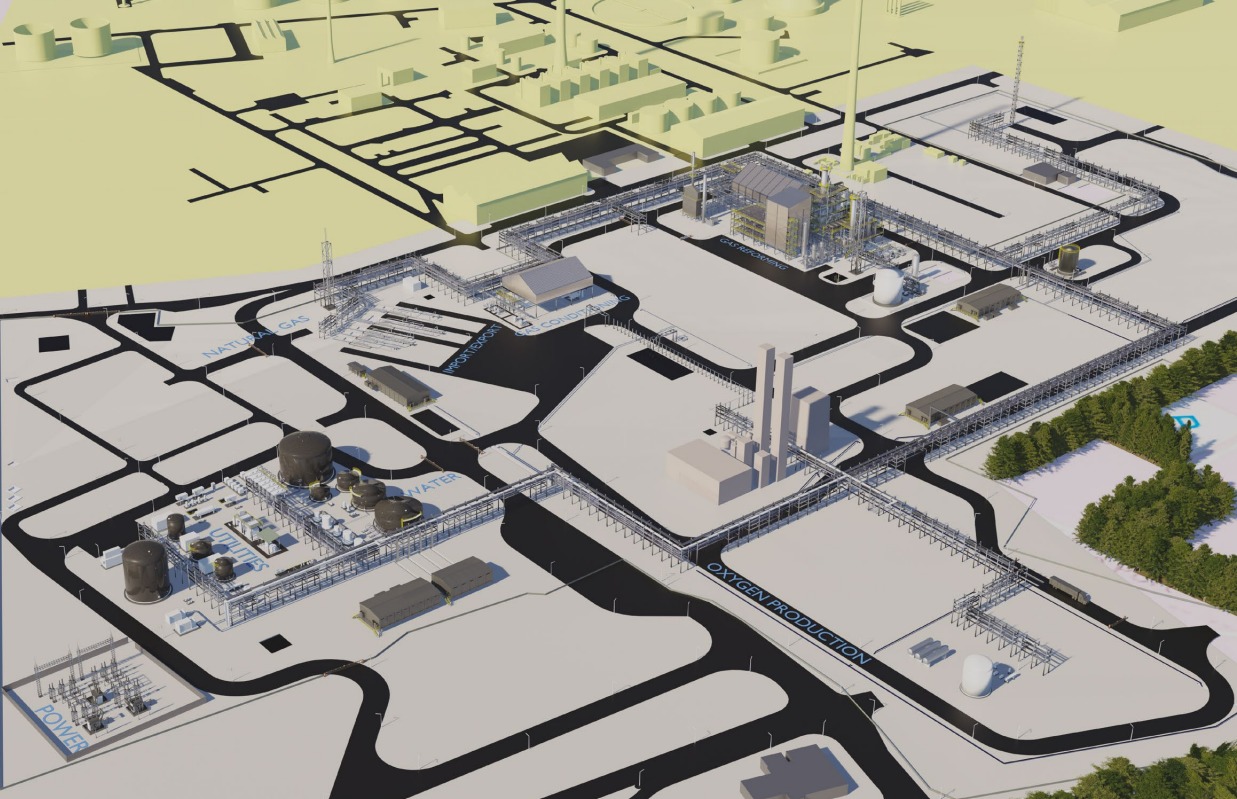

Two plants will be constructed at the site on Ellesmere Port's outskirts by the end of 2026, providing a low carbon solution to fuel vital to heavy industry. It is also planned for the second plant to have twice the capacity of the first plant.

CGI of the new low carbon Vertex Hydrogen plant at the Stanlow Manufacturing Complex.

The plant's carbon capture rate target will be 97 per cent, with the first plant producing 350MW and the second 700MW.

The report has been launched by consortium partners Essar, Progressive Energy, Kent and Johnson Matthey to share learnings as to how they are designing and developing the £1 billion ground-breaking hydrogen production plant.

The plant, to be owned and operated by Vertex Hydrogen, is being engineered by Kent and will use UK company Johnson Matthey’s best in class 'Low Carbon Hydrogen (LCH™)' technology at Essar’s Stanlow Manufacturing Complex. The 'Front End Engineering Design (FEED)' was funded by the Government’s Department of Business, Energy and Industrial Strategy (‘BEIS’) hydrogen supply competition.

The report explains how natural gas, and refinery fuel gas, will be converted into low carbon hydrogen whilst capturing carbon dioxide to be permanently stored under the sea bed in Liverpool Bay.

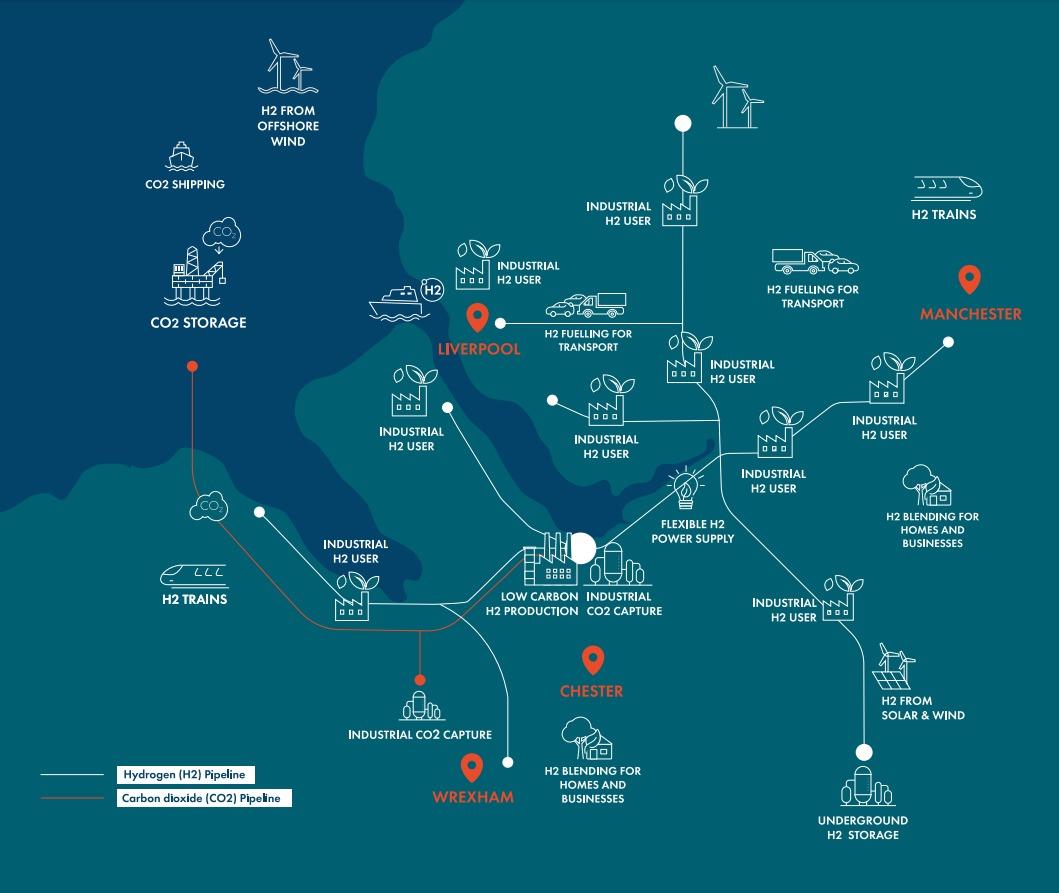

The hub will produce 1GW of low carbon hydrogen, with the first production line starting in the mid 2020s.

It will be located on the former alcohols production site in the south east corner of the Stanlow Manufacturing Complex.

A plan showing where the new HyNet hydrogen production plant will be at Stanlow. 'Area 4' was its originally planned site.

Low carbon hydrogen will replace fossil fuels in industry across the North West England and North Wales, helping the UK to decarbonise towards the nation's net zero commitments and positioning a hydrogen economy as a catalyst for low carbon growth.

Industry in the region across the chemicals, ceramics, paper, glass and flexible power generation sectors have already made commitments to reduce their carbon footprint using low carbon hydrogen from HyNet.

This includes a wide range of companies such as Tata Chemicals Europe, Encirc, InterGen, Solvay, Ingevity, Novelis, Pilkington Glass and Saica Paper.

The report follows Vertex’s submission of the company’s plans to BEIS last month to build the UK’s first low carbon hydrogen production hub with the HyNet cluster as part of the Government’s Cluster Sequencing process.

Chris Manson Whitton, director of Vertex Hydrogen, said: “Our joint team of engineers, project managers and technologists, drawn from the consortium partners, have been developing this ground-breaking project over the last two years.

"We understand how important it is for us to share the knowledge we have learnt over this time to facilitate others who are following in our footsteps. This will both ensure the UK maintains its leadership position at the forefront of the growing global hydrogen economy and enable us to move as quickly as possible towards net zero.

"The work completed to date on Vertex Hydrogen’s hydrogen production plant project demonstrates that we already have the technologies and skills within the UK workforce to design and deliver this type of project successfully.”

Jon Barden, director of Vertex Hydrogen and COO at Essar Oil (UK) Ltd, said: “Essar is committed to investing in the energy transition and, with our consortium partners, we are demonstrating how we are putting our commitment to low carbon into practice.

"We hope that by sharing our development approach, we can equip others to also play their part in achieving the UK’s net zero goals.”

Sam French, business development director for Johnson Matthey, said: “At Johnson Matthey, we are fully behind the HyNet project. What is critical now is deployment of at scale low carbon hydrogen projects.

"It has been a pleasure to work with our partners as it is clear that collaboration is critical to realisation of the UK’s hydrogen targets set out in the Ten Point Plan.”

Simon Naylor, executive vice president engineering and consulting for Kent, said: “Kent is proud to be part of this game-changing project that has been engineered by our UK Low Carbon team who are passionate about tackling the greatest challenge of our time. And ensuring that the communities of the North West of England are the first to reap the benefits of lower impact CO2 and hydrogen production.”

The UK’s first low carbon hydrogen plant will sit at the heart of the HyNet low carbon cluster.

HyNet is vital for the North West of England and North Wales to hit their net zero targets by 2050, playing their part in the fight against climate change.

By 2030, HyNet aims to be a significant contributor to the Government’s target to produce 5GW of low carbon hydrogen for power, transport, industry and homes.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here